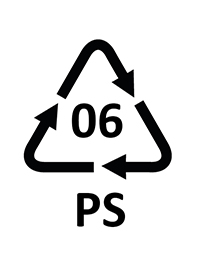

CUPS:

PS / PP/ PET / PP-Paper composite/ Paper

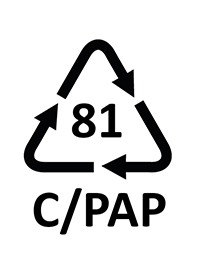

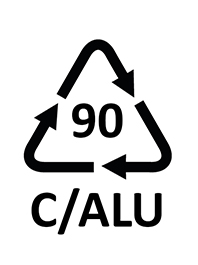

LID:

Alu / PET-Alu / Multilayer / PET / PP / Paper composite

SERVICES FROM - TO:

8.000 cups/ h – 38.000 cups/ h

HYGIENE STANDARD FROM- TO:

Ultra Clean (VDMA IV) and Aseptik (VDMA V)

CUPLine

The VMS CUPLine model provides our customers with the highest level of hygiene standards up to log6 level. Our seal-less piston fillers guarantee high filling accuracies for many years. Filling systems are Cleaning-in-Place (CIP) and Sterilizing-in-Place (SIP). The CUPline is a continuous motion, high performance (even with low viscosity products) fully servo driven filling system. In terms of product safety and hygiene the unit is fully enclosed in a "tunnel" where sterile air is fed selectively and air exchange between the outside environment and the enclosed sterile tunnel or room is significantly minimized and nearly eliminated.

As a result, the MAC-values are not only met, but even exceeded. The cantilevered servo drives are fully enclosed and isolated in the sterile area. They are easily accessible and serviceable. The space saving system control components are fully integrated reducing start-up times. All product contact areas are sterilized with saturated steam at 143°C. The sterile tunnel is cleaned with hydrogen peroxide. Further disinfection of packaging is also carried out with H2O2. The residual peroxide remaining after the disinfection process is less than 0.5 ppm while maintaining log6 levels. The innovative VMS control package can also be monitored and operated remotely through a standard smart phone or tablet.

Hygiene classes Ultra Clean and Aseptic.

- Kontifill Aseptic corresponds to the VDMA hygiene

classes IV resp. V, depending on VMS aseptic module.

CUPLine BENEFITS

Flexible with regard to different packaging materials